নির্ভরযোগ্য সরবরাহকারী শীর্ষ CAS: 80-05-7 বিসফেনল একটি 99% কারখানা সরবরাহ

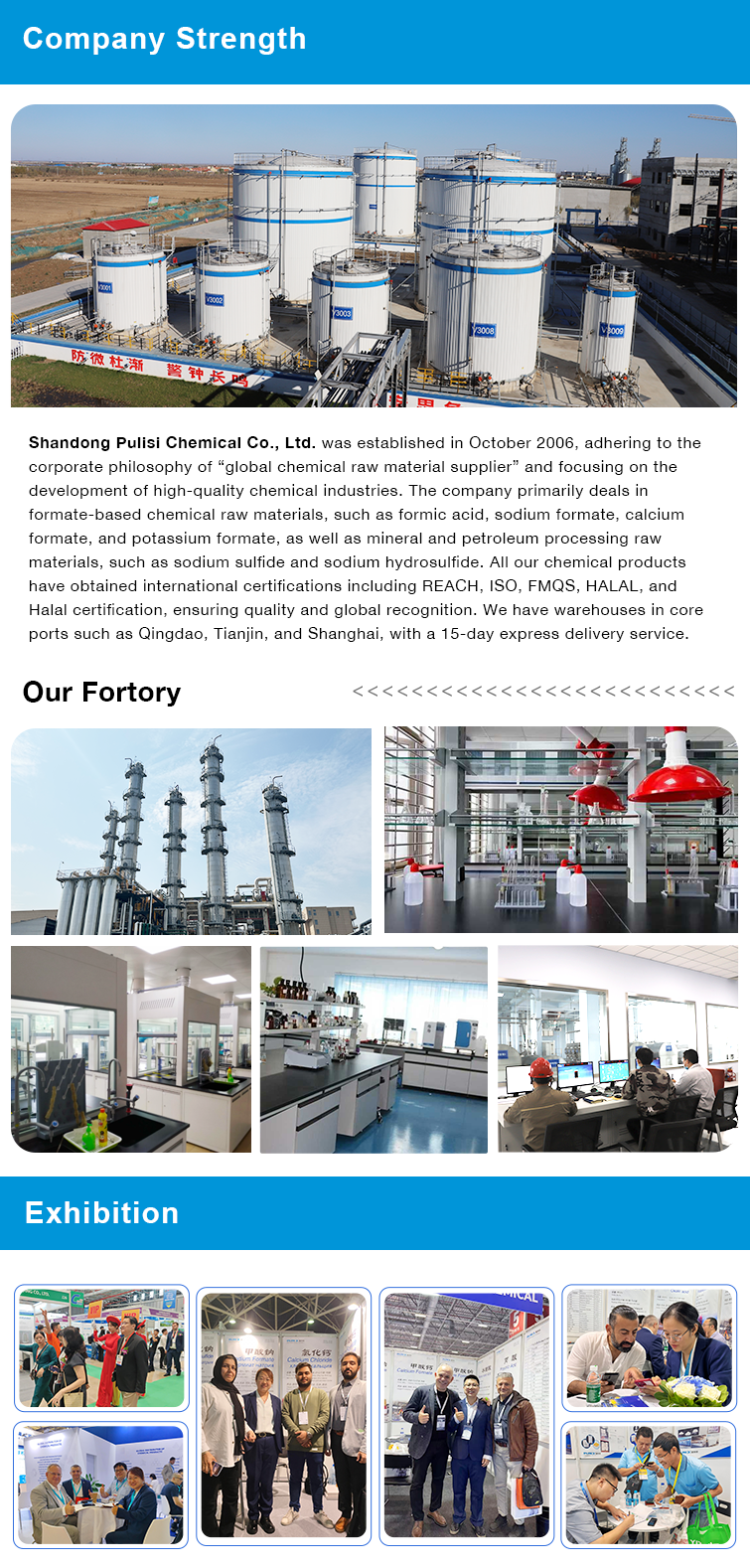

"দেশীয় বাজারের উপর ভিত্তি করে এবং বিদেশে ব্যবসা সম্প্রসারণ" হল নির্ভরযোগ্য সরবরাহকারী শীর্ষ CAS: 80-05-7 Bisphenol একটি 99% কারখানা সরবরাহের জন্য আমাদের অগ্রগতি কৌশল, আমাদের উদ্দেশ্য হওয়া উচিত গ্রাহকদের তাদের লক্ষ্যগুলি বুঝতে সহায়তা করা। আমরা এই জয়-জয় পরিস্থিতি অর্জনের জন্য দুর্দান্ত প্রচেষ্টা চালিয়ে যাচ্ছি এবং আমাদের সাথে যোগ দেওয়ার জন্য আপনাকে আন্তরিকভাবে স্বাগত জানাই!

"দেশীয় বাজারের উপর ভিত্তি করে এবং বিদেশে ব্যবসা সম্প্রসারণ" হল আমাদের অগ্রগতি কৌশল। এই সমস্ত সহায়তার মাধ্যমে, আমরা প্রতিটি গ্রাহককে উচ্চ দায়িত্বের সাথে মানসম্পন্ন পণ্য এবং সময়মত শিপিং প্রদান করতে পারি। একটি তরুণ ক্রমবর্ধমান কোম্পানি হিসেবে, আমরা সেরা নাও হতে পারি, কিন্তু আমরা আপনার ভালো অংশীদার হওয়ার জন্য যথাসাধ্য চেষ্টা করছি।

বিসফেনল এ-এর সংরক্ষণের অবস্থা "ক্ষয় রোধ, নিরাপত্তা নিশ্চিতকরণ এবং পরিবেশগত প্রভাব এড়ানো" এর মূল লক্ষ্যগুলির চারপাশে আবর্তিত হওয়া উচিত।

বিসফেনল এ (বিপিএ) এর ব্যবহার

বিসফেনল এ (বিপিএ) হল পলিকার্বোনেট, ইপোক্সি রেজিন এবং উচ্চ-তাপমাত্রা প্রতিরোধী পলিয়েস্টার সংশ্লেষণের জন্য একটি অপরিহার্য কাঁচামাল। এটি পিভিসি স্টেবিলাইজার, প্লাস্টিক অ্যান্টিঅক্সিডেন্ট, ইউভি শোষক, ছত্রাকনাশক ইত্যাদি হিসেবেও ব্যবহৃত হয়।

একটি বহুমুখী যৌগ হিসেবে, BPA ব্যাপকভাবে ইপোক্সি রেজিন, পলিকার্বোনেট, পলিয়েস্টার রেজিন, পলিফেনিলিন ইথার রেজিন এবং পলিসালফোন রেজিন উৎপাদনে ব্যবহৃত হয়। এছাড়াও, এটি পলিভিনাইল ক্লোরাইড (PVC), প্লাস্টিকের একটি অ্যান্টিঅক্সিডেন্ট, একটি UV শোষক, একটি কৃষি ছত্রাকনাশক এবং রাবারে একটি অ্যান্টি-এজিং এজেন্টের জন্য একটি স্টেবিলাইজার হিসেবে কাজ করে।

এটি রঙ এবং কালিতে অ্যান্টিঅক্সিডেন্ট এবং প্লাস্টিকাইজার হিসেবেও ব্যবহৃত হয়। জৈব সংশ্লেষণে, BPA ইপোক্সি এবং পলিকার্বোনেট রেজিন তৈরির জন্য একটি মূল উপাদান হিসেবে কাজ করে এবং এটি উচ্চ-আণবিক সিন্থেটিক যৌগের জন্য একটি গুরুত্বপূর্ণ কাঁচামাল হিসেবে ব্যাপকভাবে ব্যবহৃত হয়, সেইসাথে অ্যান্টি-এজিং এজেন্ট, প্লাস্টিকাইজার এবং কৃষি ছত্রাকনাশক হিসেবেও ব্যবহৃত হয়।

১. ডেলিভারি নির্ভরযোগ্যতা এবং কর্মক্ষম উৎকর্ষতা

মূল বৈশিষ্ট্য:

১,০০০+ সহ কিংডাও, তিয়ানজিন এবং লংকাউ বন্দর গুদামে কৌশলগত ইনভেন্টরি হাব

মেট্রিক টন মজুদ আছে

১৫ দিনের মধ্যে ৬৮% অর্ডার ডেলিভারি করা হয়েছে; এক্সপ্রেস লজিস্টিকসের মাধ্যমে জরুরি অর্ডারগুলিকে অগ্রাধিকার দেওয়া হয়েছে

চ্যানেল (৩০% ত্বরণ)

2. গুণমান এবং নিয়ন্ত্রক সম্মতি

সার্টিফিকেশন:

REACH, ISO 9001, এবং FMQS মানদণ্ডের অধীনে ট্রিপল-প্রত্যয়িত

বিশ্বব্যাপী স্বাস্থ্যবিধি নিয়ম মেনে চলা; ১০০% কাস্টমস ক্লিয়ারেন্স সাফল্যের হার

রাশিয়ান আমদানি

৩. লেনদেনগত নিরাপত্তা কাঠামো

পেমেন্ট সমাধান:

নমনীয় শর্তাবলী: এলসি (দৃষ্টি/মেয়াদী), টিটি (২০% অগ্রিম + চালানের সময় ৮০%)

বিশেষায়িত স্কিম: দক্ষিণ আমেরিকার বাজারের জন্য ৯০ দিনের এলসি; মধ্যপ্রাচ্য: ৩০%

জমা + বিএল পেমেন্ট

বিরোধ নিষ্পত্তি: অর্ডার-সম্পর্কিত বিরোধের জন্য ৭২-ঘন্টা প্রতিক্রিয়া প্রোটোকল

৪. চটপটে সরবরাহ শৃঙ্খল পরিকাঠামো

মাল্টিমোডাল লজিস্টিক নেটওয়ার্ক:

বিমান পরিবহন: থাইল্যান্ডে প্রোপিওনিক অ্যাসিড চালানের জন্য ৩ দিনের ডেলিভারি

রেল পরিবহন: ইউরেশিয়ান করিডোর দিয়ে রাশিয়ায় যাওয়ার জন্য নিবেদিতপ্রাণ ক্যালসিয়াম ফর্মেট রুট

ISO TANK সমাধান: সরাসরি তরল রাসায়নিক সরবরাহ (যেমন, প্রোপায়োনিক অ্যাসিড)

(ভারত)

প্যাকেজিং অপ্টিমাইজেশন:

ফ্লেক্সিট্যাঙ্ক প্রযুক্তি: ইথিলিন গ্লাইকলের জন্য ১২% খরচ হ্রাস (প্রথাগত ড্রামের তুলনায়)

প্যাকেজিং)

নির্মাণ-গ্রেড ক্যালসিয়াম ফর্মেট/সোডিয়াম হাইড্রোসালফাইড: আর্দ্রতা-প্রতিরোধী 25 কেজি বোনা পিপি ব্যাগ

৫. ঝুঁকি প্রশমন প্রোটোকল

এন্ড-টু-এন্ড দৃশ্যমানতা:

কন্টেইনার চালানের জন্য রিয়েল-টাইম জিপিএস ট্র্যাকিং

গন্তব্য বন্দরগুলিতে তৃতীয় পক্ষের পরিদর্শন পরিষেবা (যেমন, দক্ষিণ আফ্রিকায় অ্যাসিটিক অ্যাসিড চালান)

বিক্রয়োত্তর নিশ্চয়তা:

প্রতিস্থাপন/রিফান্ড বিকল্প সহ 30 দিনের মানের গ্যারান্টি

রিফার কন্টেইনার চালানের জন্য বিনামূল্যে তাপমাত্রা পর্যবেক্ষণ লগার

বিসফেনল এবং অ্যাসিটোন/জল শুকানো

চুল্লির বর্জ্য পদার্থ প্রথমে একটি শুকানোর টাওয়ারে পাঠানো হয়, যেখানে বিক্রিয়ার ফলে উৎপন্ন অপ্রতিক্রিয়াশীল অ্যাসিটোন এবং জল অপসারণ করা হয়। শুকানোর টাওয়ারে দুটি প্যাকিং স্তর থাকে। ফিড ইনলেট টাওয়ারের মাঝখানে থাকে এবং টাওয়ারটি মাঝারি-উচ্চ তাপমাত্রা এবং ভ্যাকুয়াম অবস্থায় কাজ করে। অ্যাসিটোন এবং জল পৃথক করার জন্য ওভারহেড পণ্যটি একটি অ্যাসিটোন টাওয়ারে পাঠানো হয়। অ্যাসিটোনকে রিঅ্যাক্টরে রিফ্লাক্স করা হয় এবং তাজা অ্যাসিটোনকে রিঅ্যাক্টরে ফিড হিসেবে ব্যবহার করা হয়, যখন জল ফেনল নিষ্কাশন ইউনিটে পাঠানো হয়। টাওয়ারের নীচের পণ্যটি শুকানোর টাওয়ার ফিডের জন্য প্রিহিটার হিসেবে ব্যবহৃত হয়। ঠান্ডা হওয়ার পরে, এটি অ্যাডাক্ট স্ফটিককারীতে পাঠানো হয় যাতে P-BPA বিসফেনল একটি অ্যাডাক্ট তৈরি হয়।